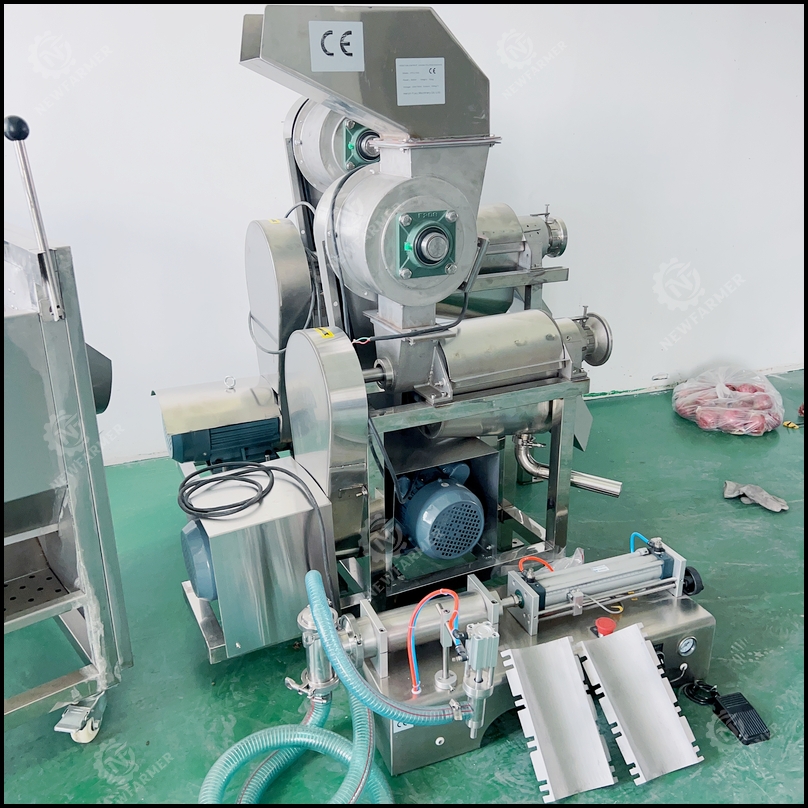

Fruit Screw Juicer Pear and Lemon Crushing Type Screw Juicer Machine

High-Quality Screw Juicer Apple Juicing Machine Ginger Crushing Machine

commercial fruit juicer coconut crushing juicing machine

Big Capacity Lemon Screw Juicer 3T Per Hour

Fruit and Vegetable Crushing Spiral Juicer, Screw Juicer Machine

Introduction of Fruit and vegetable crushing spiral juicer

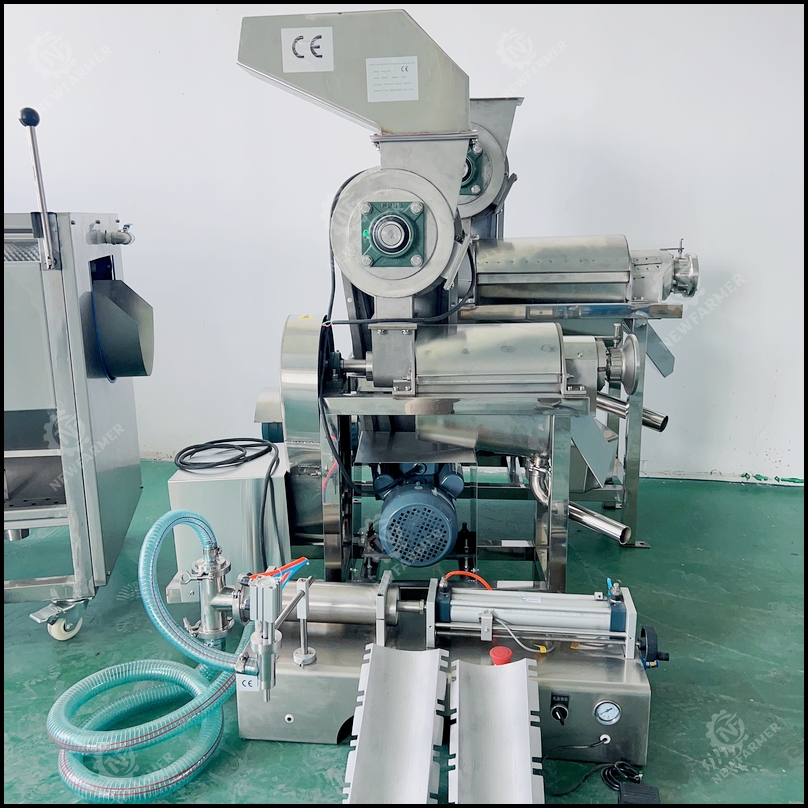

The fruit and vegetable crushing spiral juicer is a specialized device designed for efficiently extracting juice from fruits and vegetables. The crushing spiral juicer combines the functions of crushing and juicing in one machine.

Features of Fruit and vegetable crushing spiral juicer:

Efficient crushing: It is equipped with a powerful crushing mechanism that can break down fruits and vegetables into smaller pieces, ensuring maximum juice extraction.

Spiral design: The spiral structure inside the juicer helps to press and squeeze the crushed fruits and vegetables, separating the juice from the pulp.

High juice yield: With its advanced technology and design, this crushing spiral juicer can achieve a high juice yield, extracting as much juice as possible from the raw materials.

Easy to operate: The crushing spiral juicer is user-friendly and easy to operate. It usually comes with simple controls and can be easily cleaned after use.

Durable construction: Made of high-quality materials, the fruit and vegetable crushing spiral juicer is built to last and can withstand regular use.

This type of juicer is widely used in households, juice bars, and food processing industries. It offers a convenient and efficient way to enjoy fresh and nutritious juices made from a variety of fruits and vegetables.

Working principle of fruit and vegetable crushing spiral juicer:

The spiral shaft in the fruit and vegetable crushing spiral juicer pushes and squeezes the materials.

Firstly, the crushed fruits and vegetables are fed into the machine. Then, under the drive of the motor, the spiral shaft rotates and propels the materials forward.

As the materials move forward, they are subjected to increasing extrusion force. As a result, the juice is squeezed out.

The squeezed juice passes through the filter and flows out, while the residues are continuously pushed forward by the spiral shaft and finally discharged from the slag outlet.