Liquid Packaging Machine

Liquid Packaging Machine Automatic Packaging Machine

Introduction of Automatic Liquid Packaging Machine

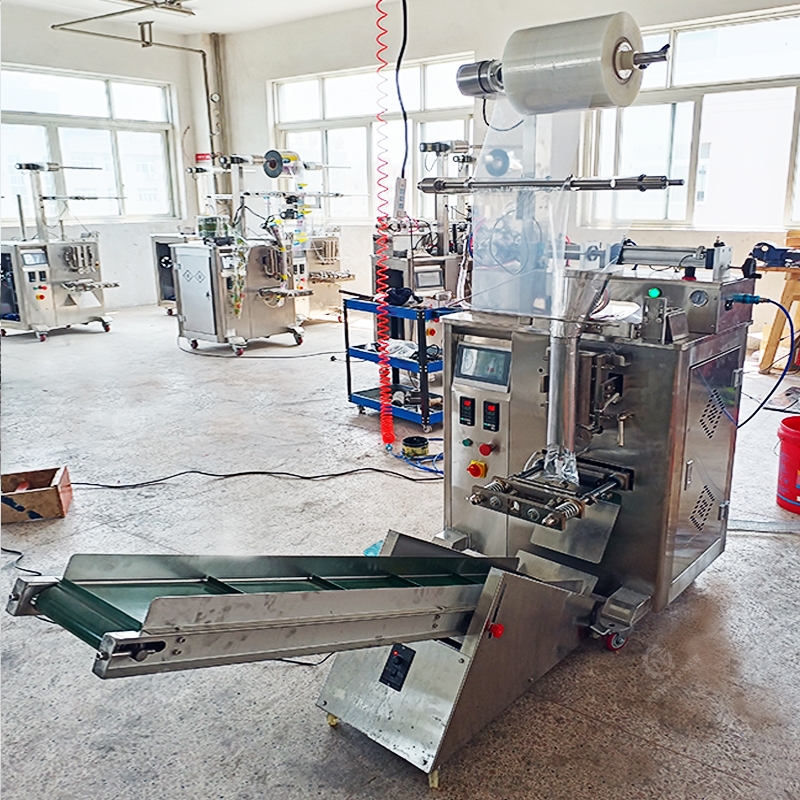

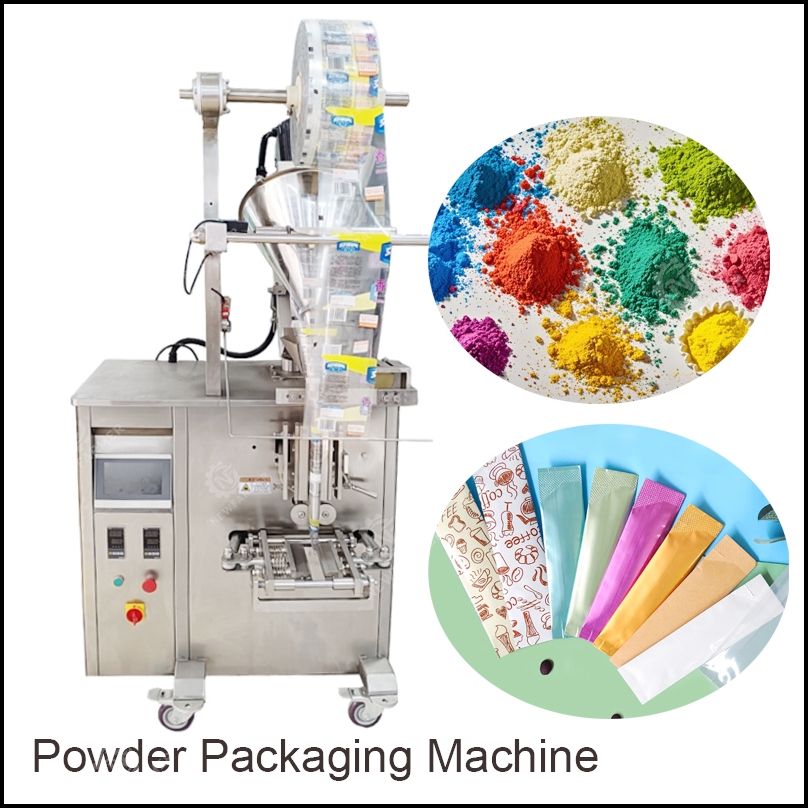

The small-dose automatic liquid packaging machine is designed for packaging small amounts of liquid. It features high automation, accurate measurement and reliable sealing. Widely used in industries like food industry, pharmaceuticals and cosmetics, it improves production efficiency and ensures product quality.

This automatic liquid packaging machine uses a piston pump to smoothly inject quantitative materials into the packaging bag through the pipeline, thus solving the adverse effect of the material with poor fluidity being retained when the general automatic packaging machine is working.

In addition, automatic liquid packaging machine can be equipped with or automatically complete the processes of metering, bag making, filling, sealing, coding, adding easy-tear notches, cutting (cutting methods: straight cut, serrated cut, continuous easy-tear cut), counting and product output in one go.

Advantage of Automatic Liquid Packaging Machine

The small-dose liquid automatic packaging machine has several advantages.

Firstly, it offers high automation, reducing labor intensity and increasing production efficiency.

Secondly, it ensures accurate dosing of small liquid volumes, guaranteeing product consistency.

The machine also has reliable sealing performance, preventing leakage and ensuring product safety.

Additionally, it is easy to operate and maintain, saving time and costs.

Moreover, it can adapt to different packaging materials and sizes, providing flexibility for various production needs.

Application of Automatic Liquid Packaging Machine:

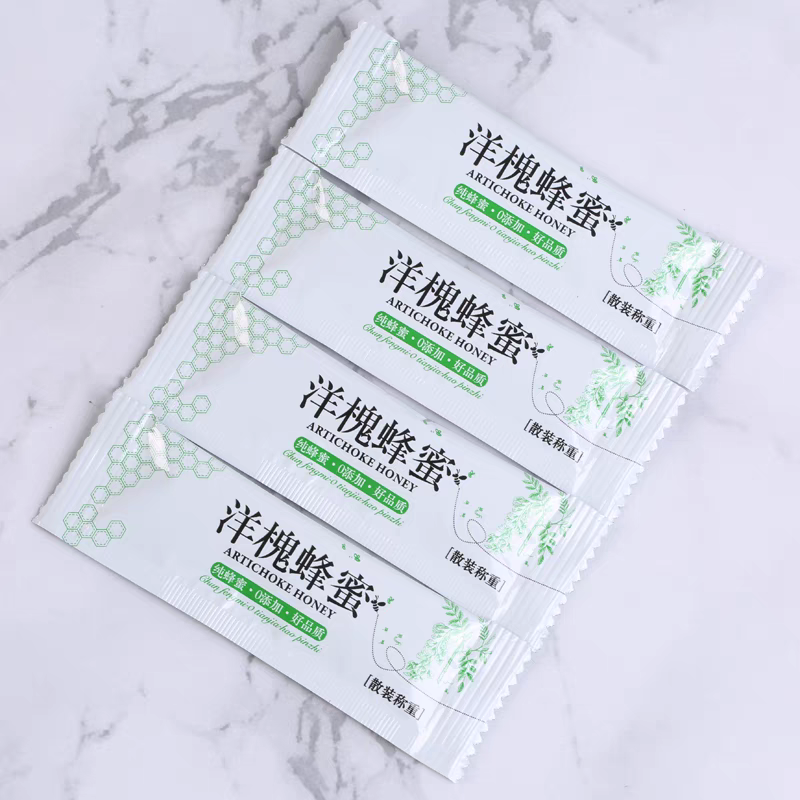

The small-dose automatic liquid packaging machine has wide applications. In the food industry, it can package seasonings like ketchup and chili sauce, as well as honey, tomato sauce.

In the pharmaceutical field, it is suitable for packaging liquid medicines in small doses.

In the cosmetics industry, it can handle products like shampoo and skincare creams.

This automatic liquid packaging machine ensures accurate dosing and reliable packaging, improving product quality and production efficiency.

It is also easy to operate and maintain, making it a valuable asset for various industries dealing with small-volume liquid and paste products.